The basic form of verifying the compliance of a product or service is quality control, which provides direct information on the correctness of the production or service process. Exercising control over the production process and striving to ensure that the final product is of the highest quality are indispensable elements of our business activity.

The essence of the product inspection process is to check its compliance with the documentation provided by the customer or the engineer’s design and to eliminate defects at the earliest possible stage of the production process. Therefore, our Quality Control Department verifies the execution of manufactured parts at the first stage, between the operations and final stages. Products that do not comply with the assumed technology (documentation) are submitted for correction or rejected.

Due to the small production series, the quality control carried out in our company is usually 100% control consisting of checking all manufactured units. In a few situations, during the production of larger series of parts, statistical control is carried out, where a batch of products is assessed based on a random sample.

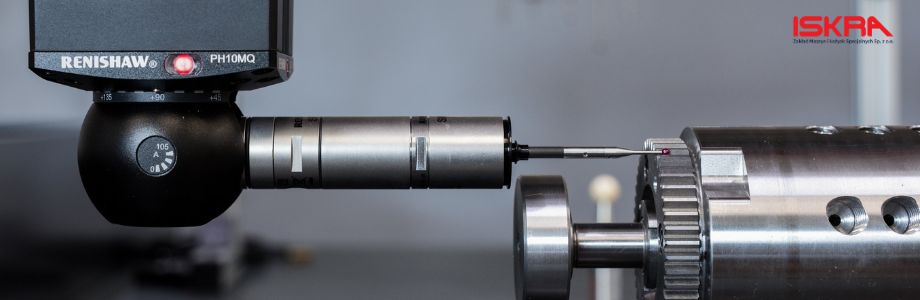

To meet the increasing demands of our customers, we improve our capabilities on many levels. In 2022 we expanded our measurement capabilities by purchasing and commissioning a Mitutoyo coordinate measuring machine (CMM).

We now can make very accurate measurements at high speed and spatial measurements. This machine measures using the coordinate technique in three axes -XYZ. The advantage of the coordinate measuring machine (CMM) is the possibility of exact measurements of elements that are difficult to measure with other measuring machines on the market.

The most important parameters of this machine are:

Range: 900x1600x600 mm

Accuracy: E0, MPE from: (1.7+0.3L/100) µm

E0, MPE:

with SP25M: (1.7+4L/1000)µm;

with TP200: (1.9+4L/1000)µm;

with TP20: (2.2+4L/1000)µm;

L = measured length [mm]

At ISKRA ZMiŁS, we measure, among others, parallelism, perpendicularity, straightness, roundness, flatness, as well as cylindricity. It allows for the maintenance of the high quality of the product, but also plays an important role in the verification and optimization of business processes. Quality control is essential in any process as it enables the monitoring of production activities and thus the elimination of errors, faults, or defects. The high quality of the product - next to the price - is one of the most important factors influencing purchasing decisions. Quality control is an inseparable element in a production company and a very important position. It is better to catch errors at the quality control station, which will protect the investor from unnecessary costs and nerves.