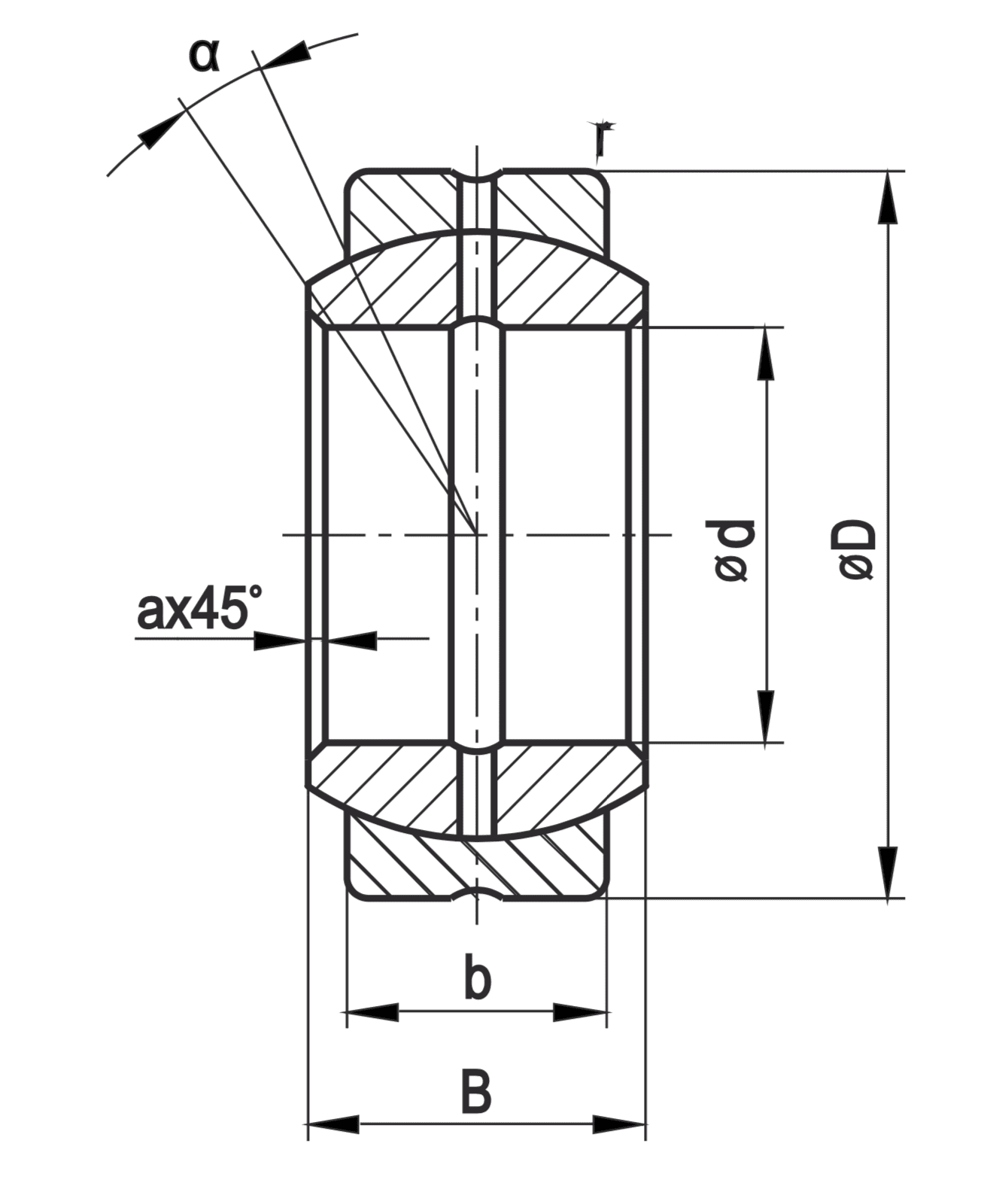

| STATEMENT | Dimensions | ||||||

| d | D | B | b | r | a | a | |

| mm | mm | mm | mm | mm | mm | degrees | |

| PGE 61> | 6 | 14 | 6 | 4 | 0,5 | 0,5 | 13 |

| PGE 6X” | 6 | 16 | 9 | 5 | 0,5 | 0,5 | 21 |

| PGE 81> | 8 | 16 | 8 | 5 | 0,5 | 0,5 | 15 |

| PGE 8X1ł | 19 | 12 | 9 | 0,5 | 0,5 | 14 | |

| PGE 1011 | 10 | 19 | 9 | 6 | 0,8 | 0,8 | 12 |

| PGE 10X | 22 | 14 | 10,5 | 0,8 | 0,8 | 13 | |

| PGE 1211 | 12 | 22 | 10 | 7 | 0,8 | 0,4 | 11 |

| PGE 12X1) | 26 | 16 | 12 | 0,8 | 0,5 | 13 | |

| PGE 15 | 15 | 26 | 12 | 9 | 0,8 | 0,4 | 8 |

| PGE 16 | 16 | 30 | 14 | 10 | 1,0 | 0,5 | 10 |

| PGE 16X | 32 | 21 | 15 | 0,8 | 0,3 | 15 | |

| PGE 17/30 | 17 | 30 | 14 | 10 | 1,0 | 0,5 | 10 |

| PGE 17 | 32 | 14 | 10 | 1,0 | 0,5 | 10 | |

| PGE 18/32 XG2> | 18 | 32 | 19 | 15 | 0,5 | 0,5 | 10 |

| PGE 20 | 20 | 35 | 16 | 12 | 1,0 | 0,5 | 9 |

| PGE 25 | 25 | 42 | 20 | 16 | 1,0 | 0,8 | 7 |

| PGE 30 | 30 | 47 | 22 | 18 | 2,0 | 0,5 | 6 |

| PGE 30/48 | 30 | 48 | 22 | 18 | 1,0 | 0,8 | 6 |

| PGE 32/50 XG2> | 32 | 50 | 22 | 18 | 1,0 | 0,8 | 6 |

| PGE 32/62 XG | 32 | 62 | 30 | 22 | 1,2 | 1,4 | 10 |

| PGE 35 | 35 | 55 | 25 | 20 | 1,4 | 1,0 | 7 |

| PGE 40/60 | 40 | 60 | 28 | 22 | 1,2 | 1,0 | 7 |

| PGE 40 | 40 | 62 | 28 | 22 | 1,2 | 1,2 | 7 |

| PGE 45 | 45 | 68 | 32 | 25 | 1,2 | 1,0 | 7 |

| PGE 50 | 50 | 75 | 35 | 28 | 1,2 | 1,2 | 6 |

| PGE 50/80 | 50 | 80 | 40 | 32 | 2,0 | 0,5 | 8 |

| PGE 60 | 60 | 90 | 44 | 36 | 1,2 | 1,2 | 6 |

| PGE 60/100 | 60 | 100 | 50 | 40 | 1,5 | 1,2 | 8 |

| PGE 60/105 | 105 | 63 | 40 | 1,0 | 1,0 | 17 | |

| PGE 70 | 70 | 105 | 49 | 40 | 1,0 | 1,0 | 6 |

| PGE 80 | 80 | 120 | 55 | 45 | 1,0 | 1,0 | 6 |

| PGE 80/130 | 80 | 130 | 75 | 50 | 1,5 | 1,2 | 14 |

| PGE 90 | 90 | 130 | 60 | 50 | 1,5 | 1,2 | 5 |

Characteristics:

Sliding Steam: steel/steel – for high load applications.

Spherical plain bearings are slide bearings. These bearing rings have spherical plain surfaces. These bearings are designed to withstand high unit loads on sliding surfaces, low-speed oscillating movements (peripheral or tilting) and variable loads.

These bearings are manufactured to ensure a slight wiping of the mating surfaces, even with very low lubrication. The sliding surfaces of both rings are subject to special finishing treatment, which ensures the lowest possible frictional resistance and high resistance to abrasion and seizure. The raceway of the outer rings features finely crystalline phosphate.

For bearings operating at high permanent loads or in the one-sided load direction, the rings are provided with grooves and holes for periodic re-lubrication. For this purpose, use normal running greases, preferably with the addition of molybdenum disulphide or lithium greases.

The bearing outer rings are made as inseparable (divided in one place). It is recommended that the dividing lines are placed in the unloaded zone when the bearing is mounted. When mounting bearings in a housing, pressure can only be exerted on the outer ring by means of a “soft” sleeve with a suitable diameter, and on the inner ring when mounting bearings on the shaft. The rings should be adjacent to the drive shafts or housings and not to their curves.

Development conditions:

Recommended journal design

- floating bearing h6

- locating bearing m6

Recommended design of luminaire sockets

- small load, floating bearing H7

- load capacity large M7

Application:

Machines and technical devices performing fluctuating movements in light industry, food, agriculture, printing, paper, tobacco and transport.

Delivery status:

Not lubricated. Wash before lubrication and installation. Note: Bearings with a bore diameter of 60mm and larger lubricated with operating grease – do not wash. If there is no contamination, lubrication is sufficient for the entire life cycle of the bearing. Protected by maintenance oil, packed in corrosion inhibited anti-corrosion paper.